Selecting metal buttons for denim jeans collections is a critical step that impacts product style expression, functional durability, and supply chain efficiency. Faced with numerous manufacturers in the market, brands require a quantifiable evaluation system.

This guide analyzes four core dimensions to focus on when screening suppliers: quality control systems, customization and craftsmanship capabilities, production and delivery capacity, and safety and environmental standards, supplemented with specific data and case studies.

1. Quality Control System: Compliance Records and Process Verification

Consistent product quality stems from systematic management, which buyers can validate through objective data.

• International Brand Audit Records:

A supplier's experience serving global brands can be indirectly verified through their audit history. For example, metal manufacturer Songji holds records of passing 72 audits for 8 international brands including GAP, Walmart, and LEE over the past 9 years. These third-party audits cover quality, social responsibility, and environmental modules.

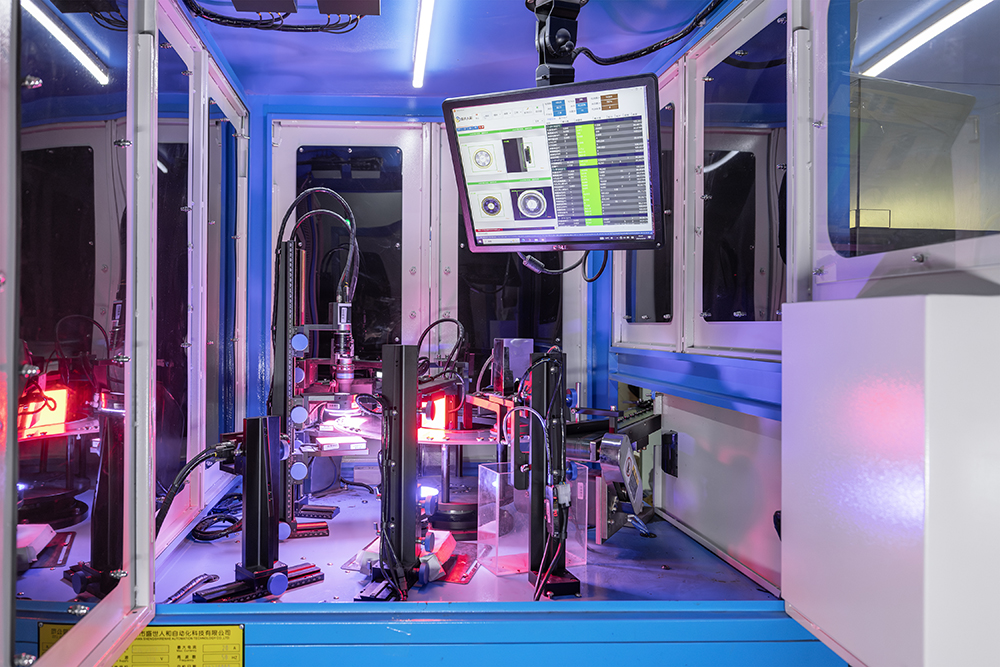

• Standardized Processes & Traceability:

Reliable button manufacturers typically establish over 150 standardized processes, controlling quality from raw materials onwards. A comprehensive batch traceability system is crucial, ensuring end-to-end information visibility from raw materials to finished products. Songji Button Manufacturer retains production and inspection data for over five years, providing concrete data support for subsequent quality management.

• Foundational Quality Certification:

ISO 9001:2015 Quality Management System certification serves as the manufacturer's foundation, indicating compliance with internationally recognized standardized requirements.

2. Customization and Craftsmanship Implementation Capabilities

For brands pursuing uniqueness, a supplier's depth of collaboration and craftsmanship expertise holds significant value.

• Full-chain Customization Services:

Evaluate whether the manufacturer offers integrated in-house OEM/ODM services spanning mold development, production, and surface finishing. This model safeguards button design confidentiality and enhances communication efficiency. For instance, Songji employs this approach to supply five-prong buttons for Armani and four-hole buttons/belt buckles for DIESEL and BURBERRY.

·Specialized Surface Finishing Techniques:

Vintage distressing is a common requirement for denim buttons, with the following three processes being prevalent:

·Chemical Distressing: Achieves consistent antique bronze effects by controlling sulfurizing agent concentration (e.g., 5%-10% sodium sulfide solution) and immersion time (10-30 minutes). Actual colorfastness is validated through 50 enzyme wash cycles.

·Physical Abrasion: Sandblasting with specific grit sizes (e.g., 80-120 mesh) or barrel tumbling creates natural worn textures, followed by passivation treatment for rust prevention.

· Composite Processes:Combining chemical and physical methods (e.g., vulcanization followed by localized polishing) creates more layered vintage effects.

· R&D Support & Selection Library: Suppliers with extensive existing product libraries provide efficient inspiration and modification foundations for brands.

3. Production & Delivery Capacity: Scalability

Meeting brands' bulk orders and rapid replenishment demands relies on manufacturers' factory scale and supply chain management.

· Capacity Metrics: Factory size is a fundamental indicator—e.g., Songji operates over 12,000 square meters of production space. Monthly consumption data (approx. 300 tons of copper and 60 tons of alloys) reflects raw material throughput and production cadence.

· Core Processes & Precision: For products like four-hole and five-claw buckles, the “one-mold-multiple-parts” production technique enhances output efficiency per unit time. For precision control, premium manufacturers maintain general dimensional tolerances within ±0.1mm, with critical functional areas achieving tolerances as tight as ±0.05mm.

· Supply Chain Role & Inventory: Serving as a supplier to global fastener conglomerates (e.g., Prym, Morito Scovill) or stroller manufacturers (e.g., WONDERLAND) indicates the factory's buttons and delivery capabilities are integrated into mainstream international supply chains. To meet replenishment demands from brands like GAP and Walmart, establishing safety stock mechanisms is a standard service process.

4. Safety and Environmental Standards

Compliance with target market regulations and consumer expectations is ensured through the manufacturer's certifications and testing protocols.

• Global Safety Certifications: OEKO-TEX Standard 100 is an internationally recognized eco-safety standard. Its Class I certification applies to infant and toddler products with the most stringent requirements. This certification requires annual renewal and tests for over 100 harmful substances.

•Eco-Material Certification: Global Recycled Standard (GRS) certification verifies the content and traceability of recycled materials in products. Currently, a relatively small proportion of manufacturers in the industry hold this certification.

•Specialized Testing Data: Suppliers' testing capabilities must cover brand-specific requirements. For example:

•Tensile Strength Testing: Standard five-claw buckles reach 90N; stroller buckles require 35KG; specialized hook designs can achieve 300KG.

•Salt Spray Test: Conducted under various conditions per client specifications (e.g., 5% concentration, 50-hour test) to evaluate corrosion resistance.

•Heavy Metal Content: Children's stroller buckles must meet lead content limits of ≤60ppm (stricter than the standard 90ppm).

Selecting the right metal button supplier for denim involves a standardized decision-making process based on verifying actual certificates, data, and compliance standards. Brands should prioritize evaluating suppliers' compliance records, process data, production capacity metrics, and certified test reports.

Manufacturers demonstrating end-to-end process control, proven experience serving international brands (e.g., providing custom solutions for LEE, NUNA, BMW), and ongoing investment in environmental and safety certifications offer more stable, reliable supply chain support for long-term brand development. By focusing on these four aspects, brands can establish partnerships with greater confidence.